Stringerless space-age foam used in a variety of quivers

Surf News Network, 24 April, 2016 – Varial Foam has been working with a dedicated group to test drive Varial in Hawaii. The below video mixes interviews, board-design discussions and freesurfs footage from the North Shore.

Mikey Bruneau, Reef McIntosh and Torrey Meister talk about their favourite Hawaiian shapes done in Varial Foam Technology. The company approached the North Shore chargers and their shapers to create a few sleds with the new technology.

Stringerless space-age foam used in a variety of quivers

Surfersvillage Global Surf News, 21 April, 2016 – Varial Foam has been working with a dedicated group to test drive Varial in Hawaii. The below video mixes interviews, board-design discussions and freesurfs footage from the North Shore.

Mikey Bruneau, Reef McIntosh and Torrey Meister talk about their favourite Hawaiian shapes done in Varial Foam Technology. The company approached the North Shore chargers and their shapers to create a few sleds with the new technology.

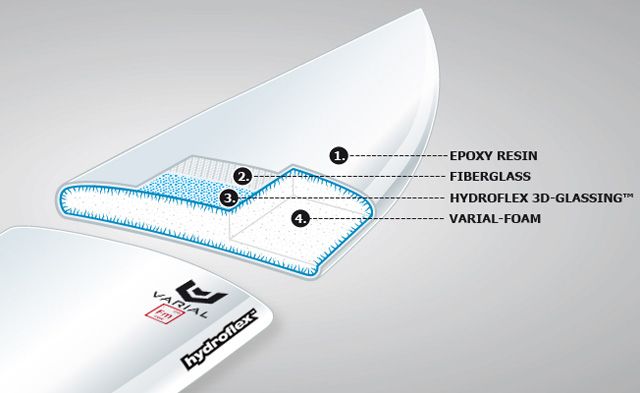

Varial Foam doesn’t use a stringer. Instead the foam is engineered to hold a similar flex pattern to that of a PU blank with a stringer. “Varial has 7X the modulus of PU or EPS foam,” says Parker Borneman of Varial. “Modulus is a technical term for the foam’s rigidity. The enhanced rigidity of Varial Foam compensates for the lack of a wood stringer.”

The advantage of going stringerless is that it eliminates the inconsistent flex properties of wood – due to the knots and grain density in wood that vary slightly from stringer to stringer. The end result is flex consistency from blank to blank.

Varial Foam doesn’t use a stringer. Instead the foam is engineered to hold a similar flex pattern to that of a PU blank with a stringer. “Varial has 7X the modulus of PU or EPS foam,” says Parker Borneman of Varial. “Modulus is a technical term for the foam’s rigidity. The enhanced rigidity of Varial Foam compensates for the lack of a wood stringer.”

The advantage of going stringerless is that it eliminates the inconsistent flex properties of wood – due to the knots and grain density in wood that vary slightly from stringer to stringer. The end result is flex consistency from blank to blank.